Description

ROLL TO ROLL / SCREEN PRESS

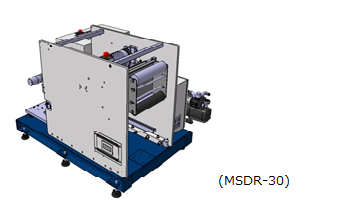

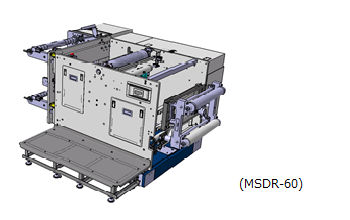

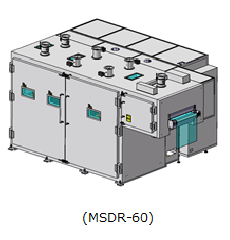

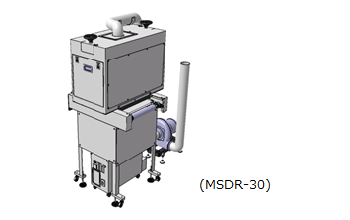

MSDR SERIES

ROLL TO ROLL CYLINDER SCREEN PRESS

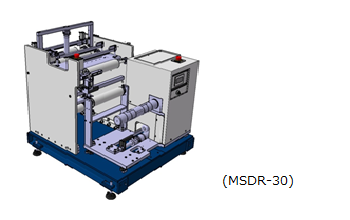

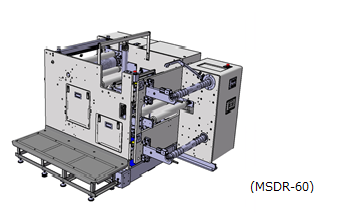

The MSDR copes with 25um thick film utilized for thin electronic parts as MLCC. Two models are available by material width: MSDR-60 (max. 600mm) and MSDR-30 (max. 300mm).

Features

- Achieved to print on 25um film that can be used for thin electronic components as the internal base material of information terminals. (MSDR-30)

- High productivity obtained by cylinder type screen printing.

–> About the advantages of cylinder screen printing machine. - High-level of printing accuracy provided by the functions of position detection and alignment via CCD camera.

- Various numerical settings are available with the touch panel.

- Reducing setup time drastically by automated screen frame initial positioning function. (MSDR-30)

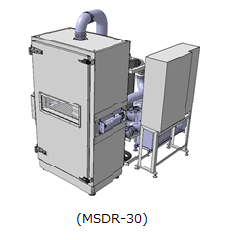

- The compact design dryers which were developed at the same time.

- Optimal line facility can be flexibly proposed for customer requirements, such as multicolor printing or combination with other processing equipment.

MSDR-30

MSDR-60

Suitable for advanced industrial screen printing, e.g., Multi-Layer Ceramic Capacitor (MLCC), Flexible Printed Circuit (FPC), biometric sensors like blood glucose sensor chip, membrane switch, and transfer printing.

Major Specifications

| Model | MSDR-30 | MSDR-60 |

|---|---|---|

| Max. web width (W) (mm) | 300 (11 13/16″) |

600 (23 5/8″) |

| Min. web width (W) (mm) | 150 (5 29/32″) |

300 (11 13/16″) |

| Web thickness (um) | 25 ~ 188 (0.001 – 0.007″) |

38 ~ 188 (0.0015 – 0.007″) |

| Max. print size (W x L) (mm) | 250 x 250 (9 27/32 x 9 27/32″) |

550 x 500 (21 21/32 x 19 11/16″) |

| Max. screen frame size (W x L) (mm) | 650 x 650 (25 19/32 x 25 19/32″) |

880 x 880 (34 3/4 x 34 3/4″) |

| Max. processing speed (sec./shot) | 3 | 3 |

* Printing size, Web thickness and Processing speed are subject to printing materials and printing conditions.

Major Features (Including Optional Equipment)

- – CCD Camera alignment system (X,Y)

- – Screen Frame Positioning by Numerical Control

- – Web Guide Devices

- – Squeegee and Flood Coater Pressure Control by Servo drive Motor

*For MSDR-30, Flood Coater Pressure Manual Adjustment - – Printing Stroke and Clearance Adjustment Control by Servo drive Motor

- – Print length adjustment fucntion

- – Plate initial positioning function *Only for MSDR-30

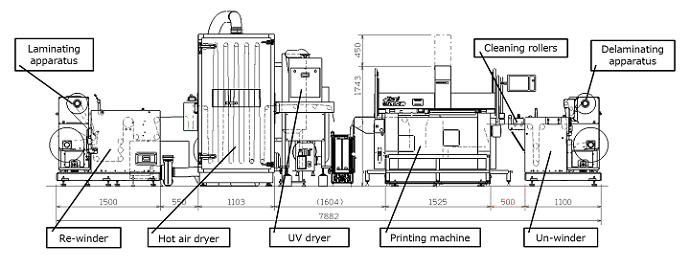

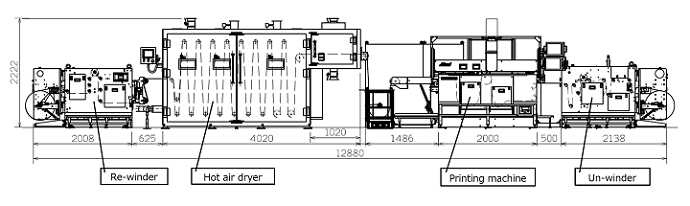

Reference layout drawings

-

- MSDR-30 Single-color printing line

- MSDR-30 Single-color printing line

- MSDR-60 Single-color printing line

Main components of MSDR Printing Line

- Un-winder

- – Unwinding speed regulation

The unwinding shaft detects the residual amount of material (web) and controls the feed amount and tension in conjunction with the winding shaft. - – Web Guide Units

Adjust the web to the printing position by the movement of the unwinding shaft (laterally slides) and the guide roller (tilts) according to the web edge sensor. - – Delaminator [option]

Peels the protective film while feeding the web. The web does not get damage since both work run at the same speed. - – Static eliminator bar [option]

- – Dust Cleaning device [option]

| Un-winder | ||

| Model | MSDR-30 | MSDR-60 |

|---|---|---|

| Chuck shaft dia. (inch) | 3 | 3 |

| Max. roll weight (kg) | 100 | 250 |

| Max. roll diameter (mm) | 400 | 600 |

| Film splicer | Standard | Standard |

| Tension setting (N) | 10 ~ 60 | 15 ~ 100 |

- Re-winder

- – Winding speed regulation

The shaft controls the winding amount and tension of material (web) in conjunction with the unwinding shaft. - – Web Guide Unit

Correct the web meandering by the movement of the winding shaft (laterally slides) and the guide roller (tilts) according to the web edge sensor. - – Laminator [option]

Attaches a film immediately after printing and drying process to protect the printed surface. The web does not get damage due to feeding in accordance with the winding tension.

| Re-winder | ||

| Model | MSDR-30 | MSDR-60 |

|---|---|---|

| Chuck shaft dia. (inch) | 3 | 3 |

| Max. roll weight (kg) | 100 | 250 |

| Max. roll diameter (mm) | 400 | 600 |

| Tension setting (N) | 10 ~ 60 | 10 ~ 70 |

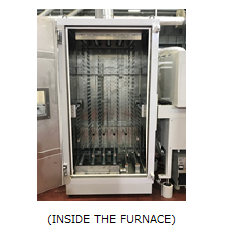

- Hot Air Dryer (Vertical, Turn type)

- – Air turn bars enable to transport web without contacting the printed surface.

- – Space-saving achieved by vertical conveyance.

- – Input/output control via the operation panel at the printing section.

| Hot Air Dryer | ||

| Model | MSDR-30 | MSDR-60 |

|---|---|---|

| Thickness of material (um) | 25 ~ 188 | 38 ~ 188 |

| Carrying Length in furnace (m) | Approx. 20 | Approx. 30 |

| Atmosphere temp in furnace (deg C) |

60 ~ 150 | 60 ~ 120 |

* The specification given above is just one example. We will propose the most suitable ones depending on the purpose and requirements of the customer’s work.

- UV curing device

- – Equipped with UV lamp x1 (high-pressure metal halide, height adjustable)

- – Input/output control via the operation panel at the printing section.

| UV Dryer | |

| Model | MSDR-30 |

|---|---|

| Thickness of material (um) | 25 ~ 188 |

| UV lamp output (w/cm) | 120 |

| Output regulation (mm) | 400 |

* The specification given above is just one example. We will propose the most suitable ones depending on the purpose and requirements of the customer’s work.