Description

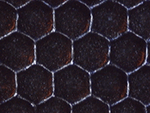

The 60 degrees hexagonal pattern has been until recent years the most common engraving in Anilox rollers. The reasons behind its standardization had been its performance advantages over previous cell patterns namely, 45 and 30 degrees engravings.

The 60 degrees hexagonal pattern allows for more cells to be compacted in an area and provides the most efficient distribution of volume. There is less wasted space (less land area) if compared to diamond shape patterns (traditional 45 deg. engraving).

This is the reason, the most uniform distribution of ink of why the 60 degrees hexagonal engraving became the norm in flexo printing.

Things have moved on since then and todays advanced laser technology has enable Anilox suppliers to develop new engravings that have surpassed the performance advantages of the conventional 60 degrees hexagonal pattern. Engravings such as the MaxFlo+ offer better transfer efficiency and an improved ink laydown than 60 degrees.